+

+

+

StandardIzed, secure, and vendor-Independent data communIcatIon for tobacco machInes

OPC UA TMC

The Challenge

- Different OEMs and machine generations don’t speak the same language.

- Data and alarms are fragmented, slowing down troubleshooting.

- Integration with MES, SCADA, or historians takes too long.

The Solutıon

- A unified data model aligned with OPC UA Tobacco Machine Communication (TMC) for tobacco machines

- OPC UA-based standardization for consistent, secure, plug-and-play integration.

Key Benefıts

Unlock seamless, secure, and scalable integration for every stage of your tobacco production line.

Vendor-neutral INTEGRATION

no lock-in, works across brands

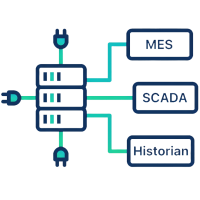

Easy MES / SCADA / hıstorıan ıntegratıon

ready-to-connect

Faster commıssıonıng

reduced engineering and startup time

Secure OPC UA

encryption, certificates, and proven reliability

Standardızed data & alarm

consistent tags across all lines

Scalable archıtecture

grows with your production needs

How It Works ?

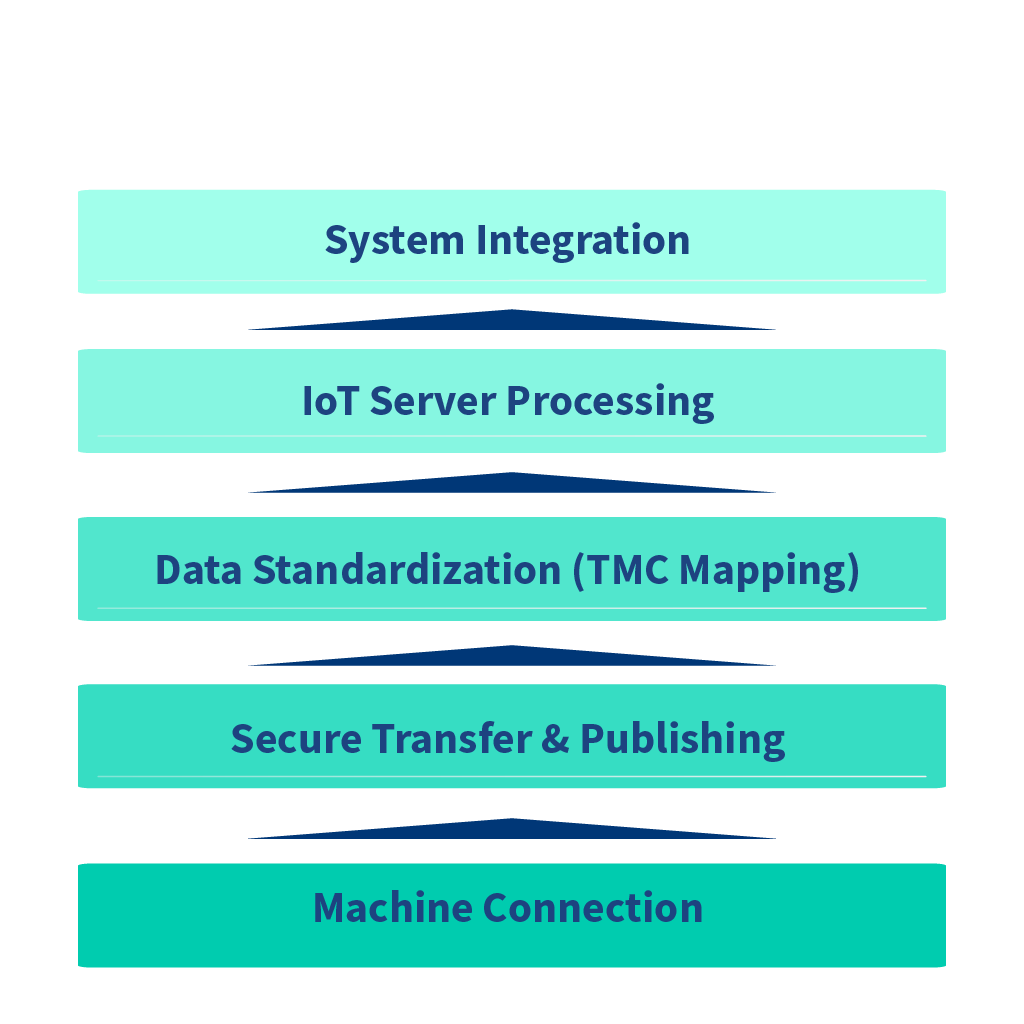

A standardized OPC UA data flow designed for seamless integration

System Integration – Standardized data seamlessly flows to MES, SCADA, historians, cloud or on-prem analytics platforms, enabling plug-and-play interoperability.

IoT Server Processing

Collected data can be validated, filtered, or transformed with formula calculations before standardization.

Data Standardization (TMC Mapping) – Raw machine data is mapped to the standardized Tobacco Machine Communication (TMC) object model, ensuring consistent data structures across all connected equipment.

Secure Transfer & Publishing – Data structured in TMC format is published through secure OPC UA with encryption and certificate-based authentication, supporting multiple protocols.

Machine Connection

TMC-compliant OPC UA servers connect directly to machine controllers or via edge gateways for legacy equipment. (This is the foundation of the data collection layer.)

Key Features

Unlock standardized, secure, and scalable integration for your tobacco production.

Features

Description

- 13 Conformance Units Supported

- Scalable Containerized Architecture

- Offline Data Logging

- Seamless Smart Data Integration

- Real-Time Monitoring & Alerts

- Central TMC Server

- OEM & PLC Compatibility

- Protocols & Edge Connectivity

- Seamless Integration

- Full compliance with TMC standards.

- Flexible deployment for lines of any size.

- Capture and store data even when disconnected

- Ready-to-use for MES, SCADA, historians, and analytics platforms.

- Unified data management for all lines and machines.

- Unified data management for all lines and machines.

- Works with Siemens S7, Allen-Bradley, Mitsubishi, Omron, and more.

- OPC UA, OPC DA, Modbus, EtherNet/IP, PROFINET, Serial and edge gateways.

- Plug-and-play connectivity with MES, SCADA, historians, and cloud applications.

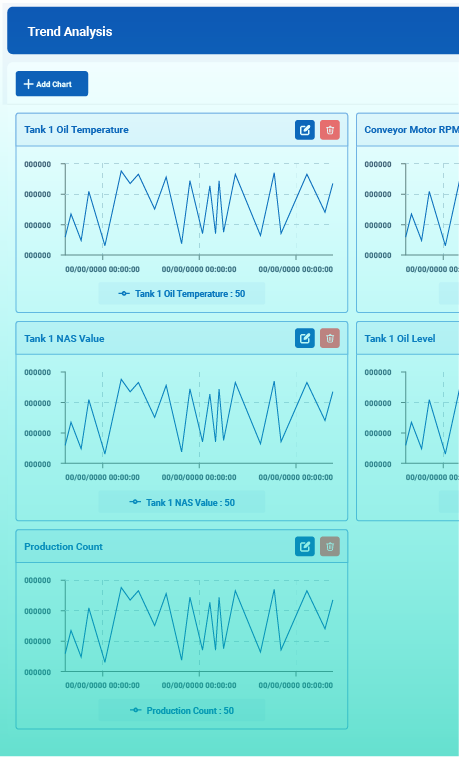

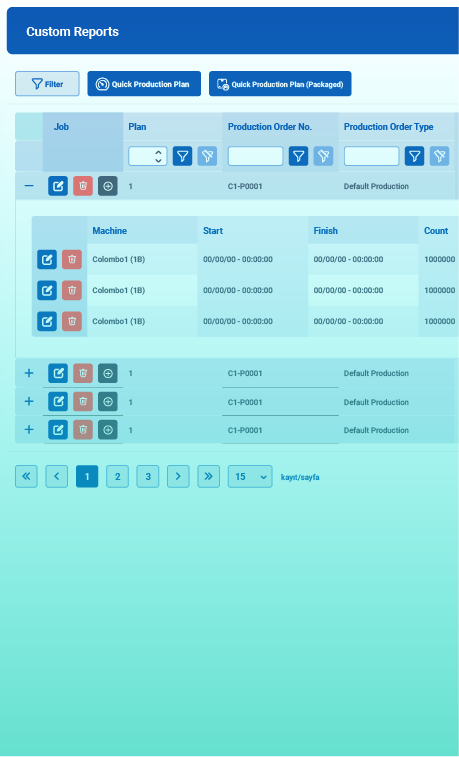

Reportıng & Monıtorıng

Real-time insights for production and quality.

LIVE Dashboards

Machıne status and KPIs at a glance.

Custom Reports

On-demand or scheduled productıon and qualıty reports

Alerts &

NOTIFICATIONS

Instant alerts for downtıme or anomalıes